Most people open their electrical panel only when something quits working. The lights head out, the microwave clock is blinking, and somebody calls from the other room about a tripped breaker. Yet the panel is the quiet center of the home's electrical system. It takes one large stream of energy from the energy and divides it into dozens of safe, workable circuits. If you understand how that distribution works, you make better choices about upgrades, fixing, and safety. You also avoid the common mistakes that result in annoyance journeys, overheated circuitry, or, in the worst cases, fire.

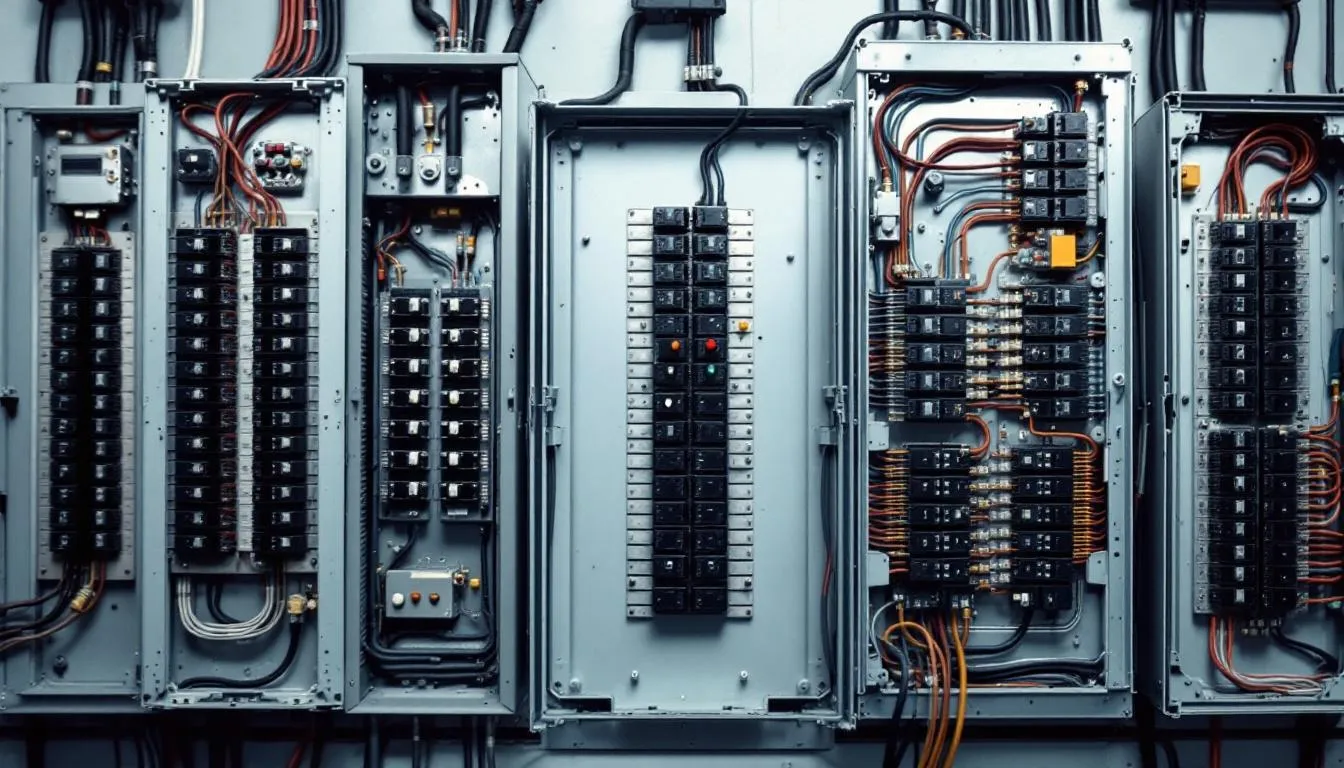

I started out pulling cable television and labeling circuits in older houses that had been tinkered with for years. You might inform which homes had mindful owners and which ones had actually lived through too many fast repairs. The panel constantly told the story. Cool bends, understandable circuit directory sites, well balanced loads, appropriate breaker types, and tidy grounding pointed to years of hassle-free service. Tangled conductors, double-lugged breakers, painted-over labels, and a missing bonding screw informed a various tale. Let's stroll through what a good electrical panel does, how power flows through it, and the practical points that matter day to day.

From the street to your main lugs

The journey starts at the service point. Power from the energy transformer shows up as two hot conductors and a neutral. In North America, this is a split-phase 120/240 volt service. Each hot leg is approximately 120 volts to neutral, and the 2 hots are 180 degrees out of stage, which provides 240 volts when utilized together. In many other parts of the world, single-phase service is 230 volts and the system architecture varies, but the principles of safe distribution inside the electrical panel stay similar.

Those conductors go through a meter, then into your service devices. In many homes, the meter base is outside and the service detach and distribution panel are inside. In others, the primary detach is incorporated into the exact same cabinet as the branch circuits. The first overcurrent device that can turn off power to the whole home is the "service disconnect." If that disconnect remains in the panel, you have a main breaker panel. If it is upstream, feeding a distribution-only cabinet, that interior cabinet is a primary lug panel.

That primary detach is not just a switch. It is a calibrated gadget with an amperage rating matched to the service size, generally 100, 125, 150, 200, or 400 amps in property settings. The service size is restricted by expert electrical panel replacement numerous things in mix: the transformer capacity, the conductors, the meter, and the ranking of the service equipment itself. Oversizing a primary breaker in a small panel does not increase capability. Whatever in the chain needs to match or exceed the load calculation.

Once past the disconnect, the hot conductors arrive at bus bars. Think about the buses as strong metal spinal columns that carry power throughout the panel. Plug-in spaces accept breakers that clamp onto these buses. Each nearby breaker "pole" rotates legs, left-right-left-right, which matters for balancing.

How the panel divides and routes power

The electrical panel divides power into branch circuits. Each circuit has an overcurrent protective device sized to safeguard the tiniest conductor on that circuit. That rule is more than a code phrase, it is a useful anchor. Breakers safeguard wire, not gadgets. If a space heater is misused, you want the breaker to journey before the wire in the wall overheats.

In a typical 200 amp residential panel, you might discover twenty to forty breaker areas. Some are single-pole 120 volt circuits. Others are two-pole 240 volt circuits for bigger loads like varieties, heatpump, hot water heater, and EV chargers. A two-pole breaker straddles both bus legs. Internally, it ties the manages together so a trip on one leg disconnects both.

Neutral and equipment grounding conductors land on separate bars in subpanels, but in the service equipment they are bonded together. This distinction trips up many DIYers. The neutral brings return present under regular operation. The equipment grounding conductor ought to not. Bonding them downstream from the main bonding point introduces parallel courses and can energize metal enclosures under a fault. In a subpanel, separate the neutral bar from the cabinet, set up a separate ground bar, and feed the subpanel with four conductors: two hots, one neutral, and one devices grounding conductor.

That bond at the service devices also connects to the grounding electrode system. Ground rods, a UFER or concrete-encased electrode, and metal water piping (if present and correctly bonded) all connect to that system. The function is not to clear a breaker throughout a brief circuit. That job comes from the equipment grounding conductor back to the panel. The grounding electrode system supports the home's electrical system to earth capacity and helps dissipate lightning or other short-term events. It also keeps the neutral reference stable.

Breakers are not all the same

Walk a finger down the rows of breakers and you will see a mix. Older homes typically have thermal-magnetic breakers that safeguard versus overloads and short circuits. Newer work adds layers: GFCI for shock security and AFCI for arc-fault fire defense, in some cases both in a dual-function breaker. Restroom and cooking area small-appliance circuits require GFCI protection. Many living areas need AFCI. Garage and outdoor circuits often need GFCI, and laundry circuits frequently need both AFCI and GFCI protection depending upon the jurisdiction and adoption of recent code cycles. If a receptacle device offers GFCI defense, you do not require to add a GFCI breaker for the very same downstream part, however you need to ensure the security actually covers the outlets where it is needed. In some cases, a dual-function breaker streamlines everything by protecting the entire circuit from the panel.

Tandem breakers are worthy of reference. These are "two-in-one" breakers that fit in a single area however serve two circuits. Panels that accept them will have specific spaces designated for tandem use and a maximum count. People pack tandems into spaces where they do not belong, chasing more circuits without upgrading the panel. I have seen this cause getting too hot and problem tripping due to the fact that the bus stabs were not created for that load pattern. Constantly match the breaker type and brand name to the panel, and follow the labeling inside the door.

Load balancing throughout the two legs

Residential split-phase panels work best when loads on the two hot legs are roughly stabilized. Perfect balance is difficult, but you can avoid extremes. If the left side brings high-current appliances and the right side carries mostly lighting, the neutral carries more present and voltage drop can increase under heavy load. A neat technique during layout is to stagger big two-pole loads and separate large single-pole loads across opposite legs. When a remodel adds an EV charger or a heat pump, I review the panel schedule, move a few single-pole breakers if needed, and tighten up the balance. It takes twenty minutes and settles in cooler buses and fewer light dimming complaints when the oven kicks on.

Wire sizes and breaker ratings, matched with purpose

Wire gauge, insulation ranking, and breaker size need to line up. As a rule of thumb in copper conductors for 60 to 75 degree C terminals: 15 amp circuits use 14 AWG, 20 amp circuits use 12 AWG, 30 amp circuits utilize 10 AWG. Aluminum wire runs larger for the exact same ampacity and needs anti-oxidant compound at terminations. Home appliances include nameplate scores that dictate circuit size. A 40 amp range wants a 40 amp breaker and wire sized appropriately to range and temperature rating. Long terms may validate upsizing wire to restrict voltage drop under load.

If a breaker journeys consistently, withstand the urge to "bump it up" a size. That relocation conceals an issue and welcomes a more serious one. Either the connected load surpasses the circuit style, or there is a fault. Detect, rearrange, or run a brand-new circuit.

What a healthy electrical panel feels and look like

An electrical panel ought to be uninteresting, in a great way. Covers fit, deadfronts are intact, breakers sit square, and labels exist and clear. The panel should not smell hot. It needs to not buzz louder than a faint hum from a transformer somewhere downstream. The neutral and ground bars need to not be loaded so tightly that conductors stack under one screw. Each conductor gets its own terminal unless the labeling particularly permits 2 of the exact same size. White insulation on neutrals remains white. If a white conductor is re-purposed as a hot leg in a cable television assembly feeding a two-pole device, it needs to be re-identified with tape or sleeving of the appropriate color.

Inside the cabinet, conductors bend with dignity. Sharp bends and stretched insulation signal stress. Cable jackets extend into the cabinet, but not up until now that you can not see the specific conductor colors at the terminals. The primary bonding screw or strap, if this is the service equipment, is present and tight. In a subpanel, that bonding screw is gotten rid of and the neutral bar isolates from the metal cabinet.

I as soon as opened a panel that had a perfect exterior, then discovered a wadded nest of splices within, covered in tape and drifting in area. Entwining inside a panel is often permitted when made with noted connectors and within the fill allowances of the cabinet, but it needs to be orderly. A splice is a connection, and every connection is a potential point of failure. Keep them to the minimum necessary.

How circuits are grouped and labeled, and why that matters

A good circuit directory is the best time-saver during a failure. Write plainly and specifically. "Cooking area outlets north wall" beats "Kitchen." "Basement lights west half" beats "Basement." Mark where shared neutrals exist, keep in mind which receptacles are on GFCI, and determine any devoted equipment circuits. If you inherit a blank or vague directory site, take an hour with an assistant, a plug-in tester, and a notebook. Switch off a breaker, discover what went dead, and write it down. You will thank yourself the next time the disposal jams and you need the right breaker without trial and error.

This is likewise where you find multi-wire branch circuits, in some cases called shared-neutral circuits. In a split-phase system, 2 120 volt circuits can share one neutral if they are on opposite legs and the breakers are handle-tied or a common-trip two-pole. If somebody has put them on the same leg, the neutral can be strained. Fixing this is as easy as moving one breaker to arrive on the opposite leg and utilizing a handle-tie or changing the set with a common-trip two-pole breaker. This is not optional. It is a security requirement and a useful necessity.

When to consider a panel upgrade

Panels do not last forever. They can serve well for 30 to 40 years if dry, undisturbed, and gently loaded, however service needs alter. Cooling upgrades, a jacuzzi, a completed basement, an induction range, or an EV battery charger push the envelope. If you discover yourself stacking tandem breakers, utilizing every last space, or counting on extension cords for permanent devices, start planning. Some legacy brand names have actually understood issues with breaker efficiency or bus connection integrity. Electricians who have actually worked in your location will know which ones to approach with caution.

A service upgrade from 100 amps to 200 amps is a typical job. Before dedicating, run a load calculation. An expert can do this quickly and consider diversity of loads, responsibility cycles, and the specifics of your heating and water heating unit. All-electric homes with heatpump and EV charging frequently benefit from 200 amps. Some families get by with load management devices that throttle automobile charging or water heating when other loads increase. Those gadgets can save cash if trenching or utility upgrades are expensive, but they include complexity and points of failure. A tidy 200 amp service with appropriate areas offers long-lasting simplicity.

Safety devices and modern requirements

Codes evolve due to the fact that innovation and real-world experience expose spaces. GFCI multiplied after statistics revealed its clear impact on reducing shock incidents. AFCI outgrew home fire data that traced ignition sources to damaged cords and loose connections that did not journey thermal-magnetic breakers. Now, dual-function breakers bring both innovations into many circuits. Rise protection at the service has also ended up being common. Whole-home surge protective gadgets clamp down short-term voltage spikes from lightning or utility changing occasions. They do not make low-cost power strips obsolete, however they assist protect sensitive electronic devices and extend equipment life. When I install a brand-new panel, I normally consist of a Type 2 surge protector connected to a two-pole breaker near the top of the bus, with brief result in lessen impedance. Brief and direct matters for surge devices.

Working inside the panel, risks and boundaries

There are 2 parts of an electrical panel you must deal with differently. Downstream of the main breaker, turning that breaker off de-energizes the buses and the branch circuits. Upstream of the primary, the service conductors remain live, even with the main off. That implies the lugs where the energy power enters are dangerous no matter what you make with the breaker. If you are not trained, do not reach near those lugs. Even many pros choose to arrange an utility detach or utilize meter-pull procedures when moving or changing a panel to eliminate that hazard.

If you do minor jobs like labeling circuits or swapping a basic breaker of the correct type, you still need to be precise. Confirm the primary is off, validate with a meter, and keep one hand clear when working near buses to prevent bridging a course through your body. Utilize a flashlight and take your time. Torque matters. The majority of breaker and lug terminals have actually defined torque values. A terminal that feels "tight" by hand may be under or over torqued. Under torque heats up under load. Over torque damages threads or conductor hairs. Electrical experts bring torque screwdrivers for this reason.

Common pain points, and what they usually mean

Flickering lights when large devices start normally point to voltage drop on a heavily loaded leg or at a loose neutral connection. I as soon as traced a persistent flicker to a rusty neutral lug on the service entryway. The repair brought back stable power and ended intermittent GFCI trips in the kitchen.

A breaker that trips at random intervals typically has a pattern hiding in plain sight. Note what runs at the time. Area heating systems and hair dryers are traditional 12 amp devices that quickly press a 15 amp lighting circuit beyond its limit. The service is not a larger breaker. It is a brand-new devoted circuit or better load discipline.

Warm breakers, staining around a stab, or a breaker face that looks baked are red flags. Heat marks can show poor contact between the breaker and the bus. Bus damage tends to spread out. Replacing one breaker may not resolve a damaged stab. At that phase, a panel replacement is the much safer course.

Undersized neutrals in older aluminum cable setups cause a particular set of problems, especially under non-linear electronic loads. Modern homes do not have the harmonic content of a commercial workplace loaded with power supplies, but set-top boxes, battery chargers, and LED chauffeurs accumulate. If you are rewiring a home from the 1960s or 1970s with aluminum branch circuits, consider an extensive strategy that consists of appropriate terminations, antioxidant substance, CO/ALR or AL compatible gadgets where required, or pigtailing to copper with listed adapters. Piecemeal repairs just kick the can.

Where subpanels assist and how to feed them correctly

Garages, additions, and finished basements typically gain from a subpanel. A subpanel gives you brief wire runs, more spaces for future circuits, and less mess in the primary. Feeding a subpanel is simple however need to be done easily. Run a four-wire feeder sized for the load and range. Secure it with a two-pole breaker in the main. In the subpanel, isolate neutral and ground. Drive a local grounding electrode just if required, and bond it to the equipment ground, not to the isolated neutral. Label the feeder breaker and the subpanel directory site. Keep the subpanel in a location that meets working clearance rules. Tight closets and spaces above laundry machines do not qualify.

One information many people miss out on is feeder load diversity. If the subpanel serves a workshop with periodic heavy tools, the feeder can be smaller than the amount of all tool nameplates because they will not run all at once. If it serves a basement with a mini-split, dehumidifier, server rack, and kitchen space, the task cycle and simultaneity may be higher. Plan based on reasonable usage, not simply want lists.

Weather, environment, and enclosure choices

Not all electrical panels reside in conditioned area. Garages can be humid, and coastal areas are hard on steel. Outdoor service devices need to be ranked for wet places. Gaskets, weep holes, and tight penetrations keep water out and let condensation escape. Seal around avenue entries with appropriate fittings. Avoid top-entry flex into outside panels where wind-driven rain can wick along the spiral. If the panel is in an utility room, think about lint and deterioration. Panels like clean, dry, and cool. Provide space to breathe.

A small amount of maintenance goes a long way

Home electrical systems are not maintenance-free. Every 2 to 3 years, open the panel, blow out dust with dry air, and look for signs of heat, rust, or loose terminations. Cycle the main breaker a number of times. Exercising breakers assists keep systems free. Replace labels that have smudged. If breakers journey due to age-related weakening, change them with the precise noted type. Budget plan for an expert assessment every decade or after significant renovations.

Practical checkpoints for homeowners

- Keep the location in front of the electrical panel clear for a minimum of 3 feet, floor to ceiling, and 30 inches wide. Update the circuit directory so it specifies and legible, using a pencil you can revise. Verify that GFCI and AFCI protection exists where needed, and test GFCI devices month-to-month utilizing their test buttons. If a breaker journeys repeatedly, recognize the connected loads and call a professional if the cause is not obvious. Before adding big appliances or an EV battery charger, have a load computation performed to figure out if your electrical panel and service can support it.

The peaceful value of doing it right

A sturdy electrical panel fades into the background of daily life. It does not buzz or odor, and it does not become warm to the touch. Breakers journey seldom and for easy to understand factors. The circuit identifies make sense, the enclosure is tidy, and the system keeps up as your needs alter. When you include a heat pump or a vehicle battery charger, the path is clear due to the fact that the basics remain in place.

I have actually changed panels that served for forty years without a single odd occasion, and I have changed three-year-old installs that failed due to the fact that they cut corners. The distinction was not brand or price as much as discipline and respect for the basics. Match breaker types to the panel, size conductors conservatively, keep neutrals and grounds where they belong, stabilize the load, safeguard where people and water satisfy, and document what you have. Those actions turn a box of copper and steel into a reliable heart for the home.

If you only do something this weekend, open your electrical panel door and read the directory site. If the words do not help you discover the cooking area lights in a pinch, take the time to repair that. If you see empty knockouts without plugs, missing out on screws on the deadfront, or scorched breaker deals with, generate a licensed electrical contractor. A little attention now keeps the electrons flowing where they should, and keeps you from discovering your electrical system by flashlight.